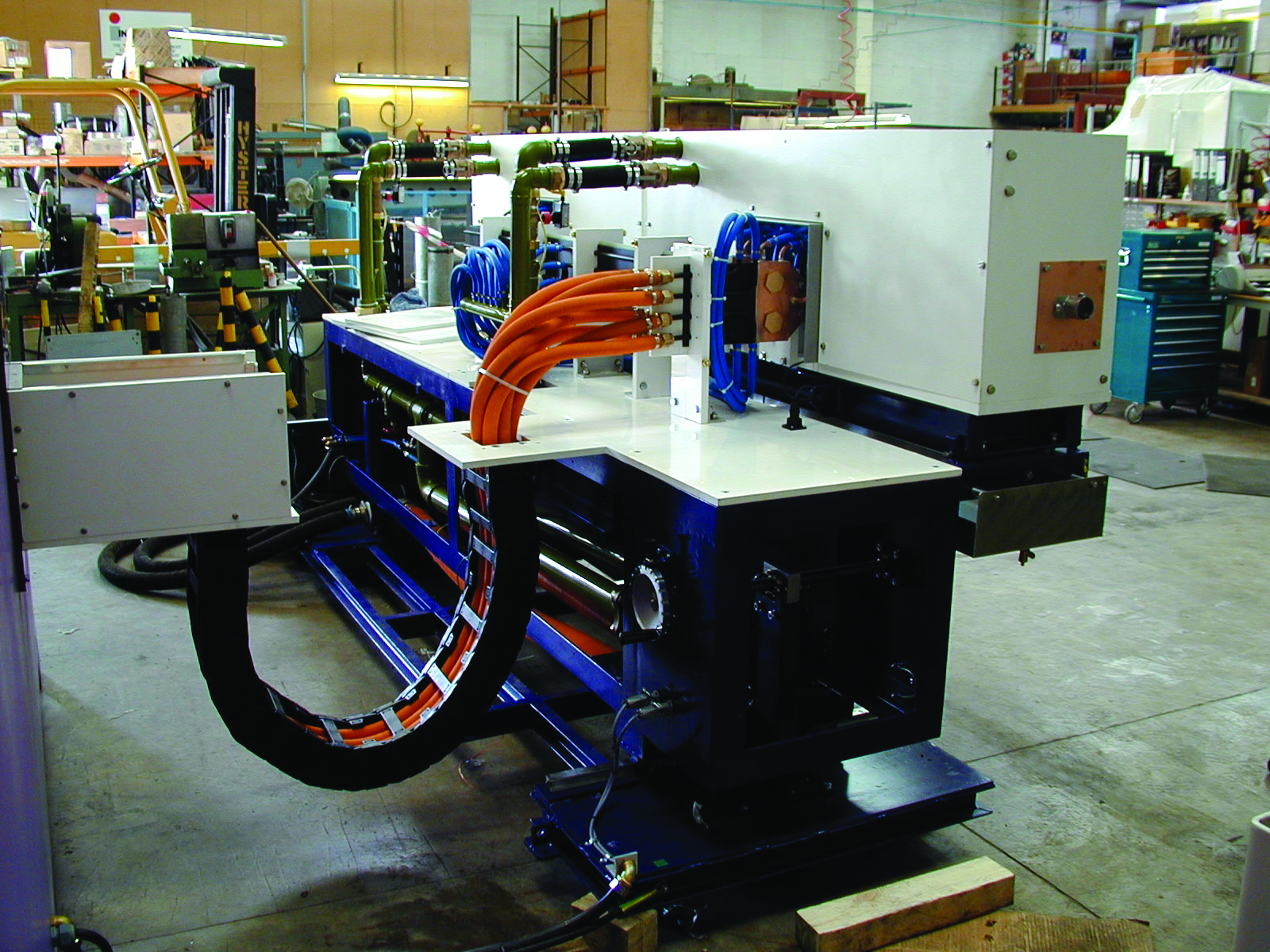

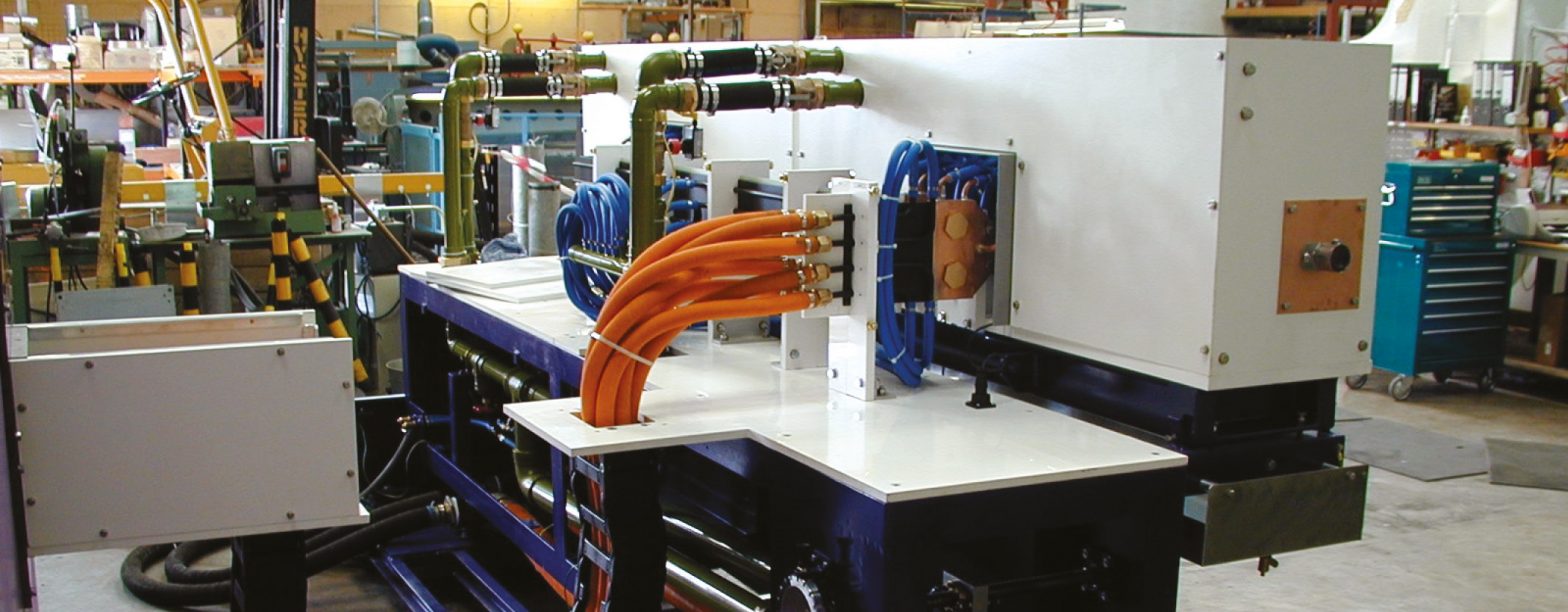

Aluminium Tube Annealing

With over 50 years of knowledge and experience Banyard’s products are built to last. Our in-line induction Aluminium Tube Annealing systems are manufactured from the highest quality materials, ensuring it is robust and built for a life time of hard labour. This space saving Aluminium Tube Annealing solution comes in a compact design occupying a relatively small footprint when compared to a standard minimal line.

Banyard induction Aluminium Tube Annealers are designed to anneal by induction heating and water quench aluminium tube ranging from 6mm to 30mm in diameter at speeds of up to 800m/min prior to drawing.

Do you need further information? Do you need a detail explanation on how our products can help your business?

Why not call one of our in-house Induction Experts and we can work with you to provide the best solutions.

Features

Highly engineered a typical Banyard Aluminium Annealing system can be moved easily from line to line as and when required. The versatility of our annealing system become evident as you have the benefit to quickly move the system off-line for the processing of non-annealed tube.

- Highly engineered, a typical Banyard Aluminium Annealing system can quickly traverse ‘off-line’ for the production of non-annealed tube.

- Well proven, using the latest Inductotherm Digital IGBT Medium Frequency Power Convertors

- Specially designed with an environmentally friendly quench system ensures that the annealing process is fully controlled.

- Proven mechanical design /heavy duty construction provides reliability and durability.

Tech Specs

- High production rates deliver highest quality product possessing optimum grain growth size and resultant tube hardness.

- Processes a range of tube measuring from 6mm to 30mm in diameter

- Achieves speeds of up to 800m/min prior to drawing.