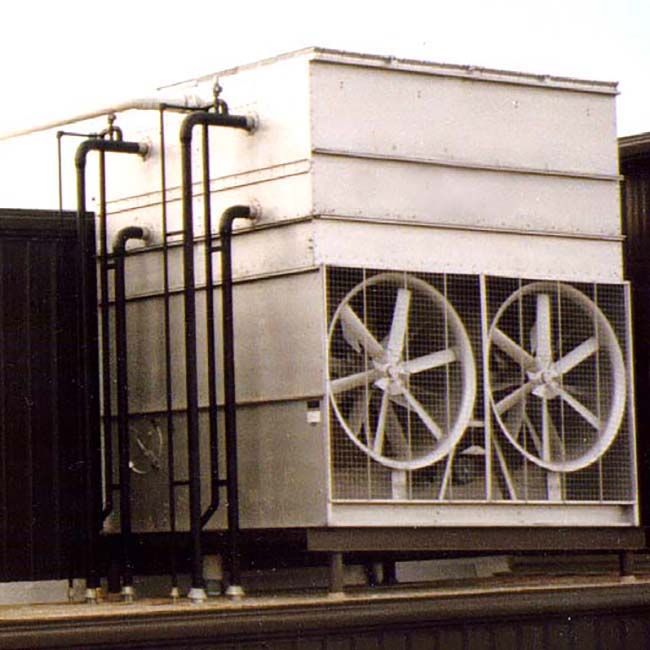

Open Evaporative Cooling Systems

Open Evaporative Cooling Systems are designed for simple operation and maintenance.

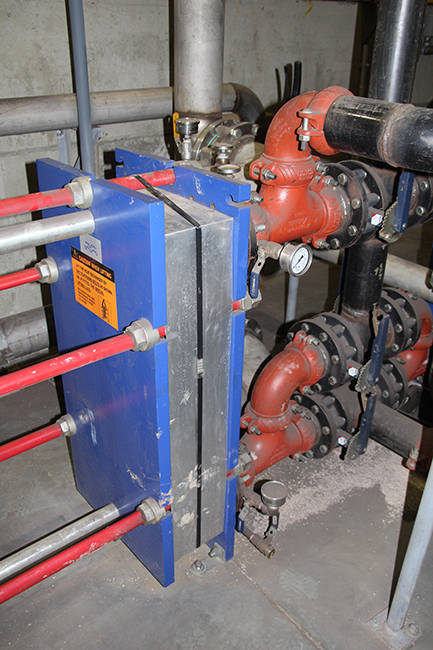

Typically a water-to-water heat exchanger is used for heat transfer between cooling tower, furnace and power supply. Open Evaporative Cooling Systems allow for the possibility of dual spray pumps and heat exchangers and can be used for both de-ionized and non-deionized systems. With these systems multiple closed systems can be cooled using a single tower. Advantages of these systems include:

- Lower costs: The tower and heat exchanger package is typically about half the cost of a traditional closed industrial tower.

- Capacity flexibility: By using a plate type heat exchanger these systems provide the flexibility needed to add or remove plates.

- Ease of maintenance: The plate type heat exchanger can be easily opened and cleaned to maintain optimum efficiency.

Larger systems often require coldwell tanks which can be supplied by either the customer or by Inductotherm. Inductotherm-supplied coldwell tanks are easy maintenance, low investment and excellent for cooling year round.

Tech Specs

| Standard Features | Optional Features | Plastic Tower Features | Inductotherm Supplied Coldwell Tank Features | Factory Tested |

|---|---|---|---|---|

| External Water-to-Water Heat Exchanger for Ease of Maintenance | Plastic Towers for Higher Cycles of Concentration and can Operate with Sea Water for Special Applications | Lighter than Traditional Steel Towers | Level Controls for Pump Protection | Critical Components |

| Flexibility to Add or Remove Plates for Adjusting Capacity | Guaranteed Tower Shells for 15 Years | Anti-Vortex Device for Pump Protection | ||

| The Ability to Cool Multiple Closed Systems | Internal Strainers for Pump Protection | |||

| Usable for Both Deionized and Non-Deionized Systems | Available with Conductivity Meter for Bleed and Control | |||

| No Condensation Problems When Used with Inductotherm Control System | Available with Internal Baffling for Debris Removal | |||

| Minimum Corrosion, Scaling and Electrolysis | ||||

| Low Investment Cost | ||||

| No Coolant Contamination | ||||

| Completely Closed-Loop Pressurized Circuit | ||||

| Water-Cooled Design | ||||

| Reliable Year-Round Cooling | ||||

| Abnormal Temperature Protection | ||||

| Audible and Visible Alarms | ||||

| Full-Access Water Pumping Modules |