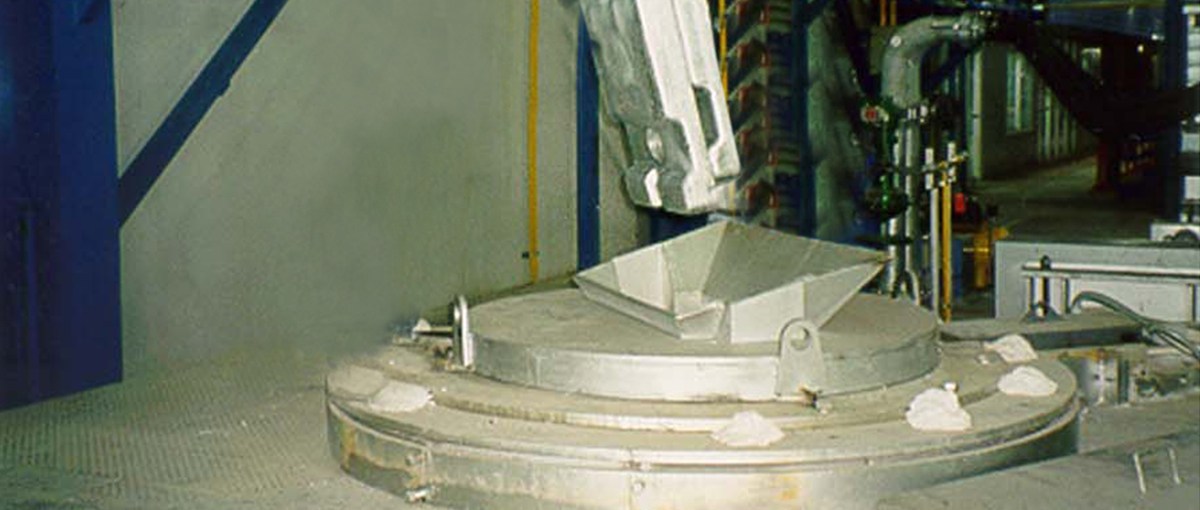

Pre-Melting Pots

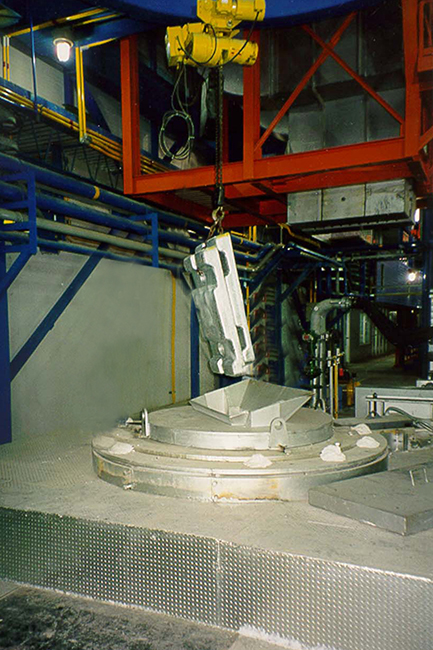

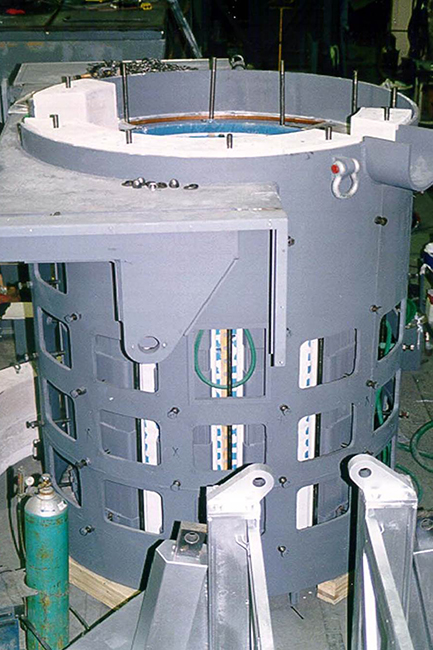

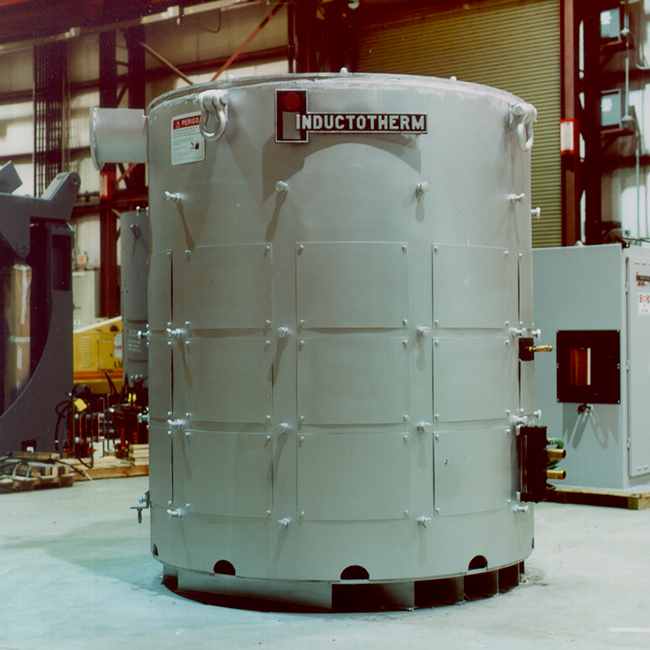

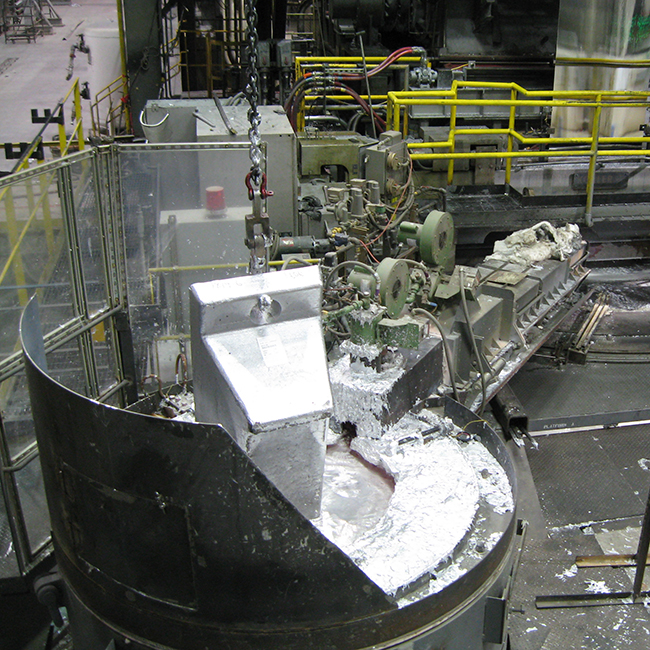

Pre-Melting Pots are available in both channel and coreless versions. These may be used for alloying including Alu-Zinc alloys. Pre-Melting Pots help to minimize the dross that can otherwise build-up in the main coating pot. Launder options are available for transferring molten metal at the proper temperature from a Pre-Melting Pot to the main Coating Pot and offer other benefits.

Features

Pre-Melting Pots are primarily used to replenish the main coating pot. These are important with a channel-type coating pot installation because the clog-causing dross created during the melting of ingots occurs in the pre-melt pot and not during the coating process. This allows for:

- Minimized wear or clogging of the channel during operation

- Minimized temperature variations in the main pot usually caused by ingot insertion

- Better quality product and less dross accumulation in the coating pot

Launder options are available for transferring molten metal at the proper temperature from a Pre-Melting Pot to the main Coating Pot and offer the following benefits:

- Minimize oxidation of the alloy

- Can be heated by either gas burners or an electrical system mounted to the optional insulated launder cover

- Are available as either overflow (angled) or flooded (level)

Tech Specs

| Capacities | Standard Features | Optional Features | Factory Tested |

|---|---|---|---|

| Contact Inductotherm for Custom Solutions | Air-Cooled Twin Loop Inductors up to 500 Kilowatts | Open Gas Heated Launders | Critical Components |

| Water-Cooled Twin Loop Inductors up to 750 Kilowatts | Covered Gas and Electric Heated Launders | ||

| Hybrid Water and Air-cooled Inductors up to 500 Kilowatts | Charging Covers | ||

| Coreless Type |