Quench and Temper

Overview

Thermatool’s Quench and Temper lines feature the most widely used and popular solid state induction power supplies available. With over 30,000 units installed worldwide for melting, heating, and heat treatment applications, the model VIP induction power supply is the most advanced technology accessible. In addition, Thermatool’s advanced precision slot quench has revolutionized the heat treat market and surmounted long standing limitations to tubular and bar quenching. Effective hardening and tempering requires the ability to deliver uniformly heated material to achieve optimum product straightness and minimal cracking through the quench. The combination of the latest computerized process controls in heating and quenching has benefited numerous industries that require quenched and tempered product. End users producing large pipe for the OCTG industry, food grade tube and pipe, and hardened and tempered bars are able to meet physical material properties demanded in many markets utilizing the Thermatool quench and temper line.

Smart Heat Control

Thermatool’s state-of-the-art smart heat control technology offers the next generation in induction heat treat technology for pipe, tube and bar processing. Proven temperature control feedback and process modeling are integrated to achieve optimal hardening and tempering results. This technology allows the operator to maintain better control over heating rates and product temperature when using multiple coil (inductor) induction heat treat units. Thermatool’s smart heat intuitive control software promotes recipe creation and recall for repeatable process setups, control and results.

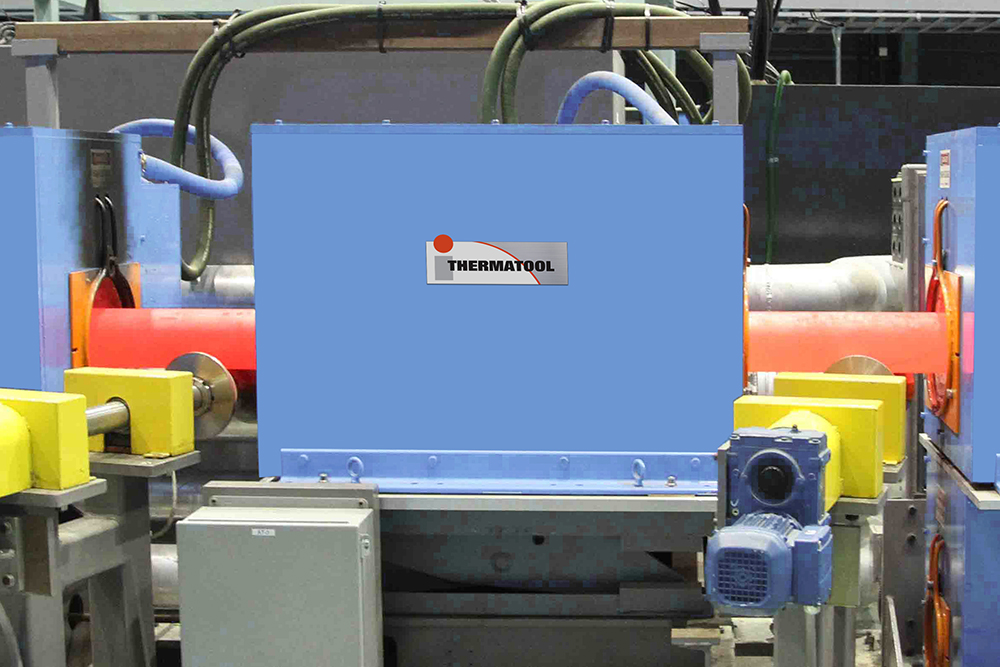

VIP Power Supplies

Thermatool shares the VIP design with the Inductotherm Group of companies with an outstanding installed base of over 30,000 of these power supplies worldwide. These same power supply designs are used in various industries such as melting, heat treating, vacuum refining, full body tube heating as well as seam annealing. This power supply design is very modular and ranges in sizes from 50 kW to over 38 MW, 0.2 kHz to 10 kHz applications. They feature intelligent microprocessor-based digital controls and are engineered to operate at a constant high-power factor regardless of power level, while generating low harmonics and voltage distortion. Harmonic and voltage distortion is further reduced in larger units by designing the equipment to accept 6, 12, or even 24 input phases.

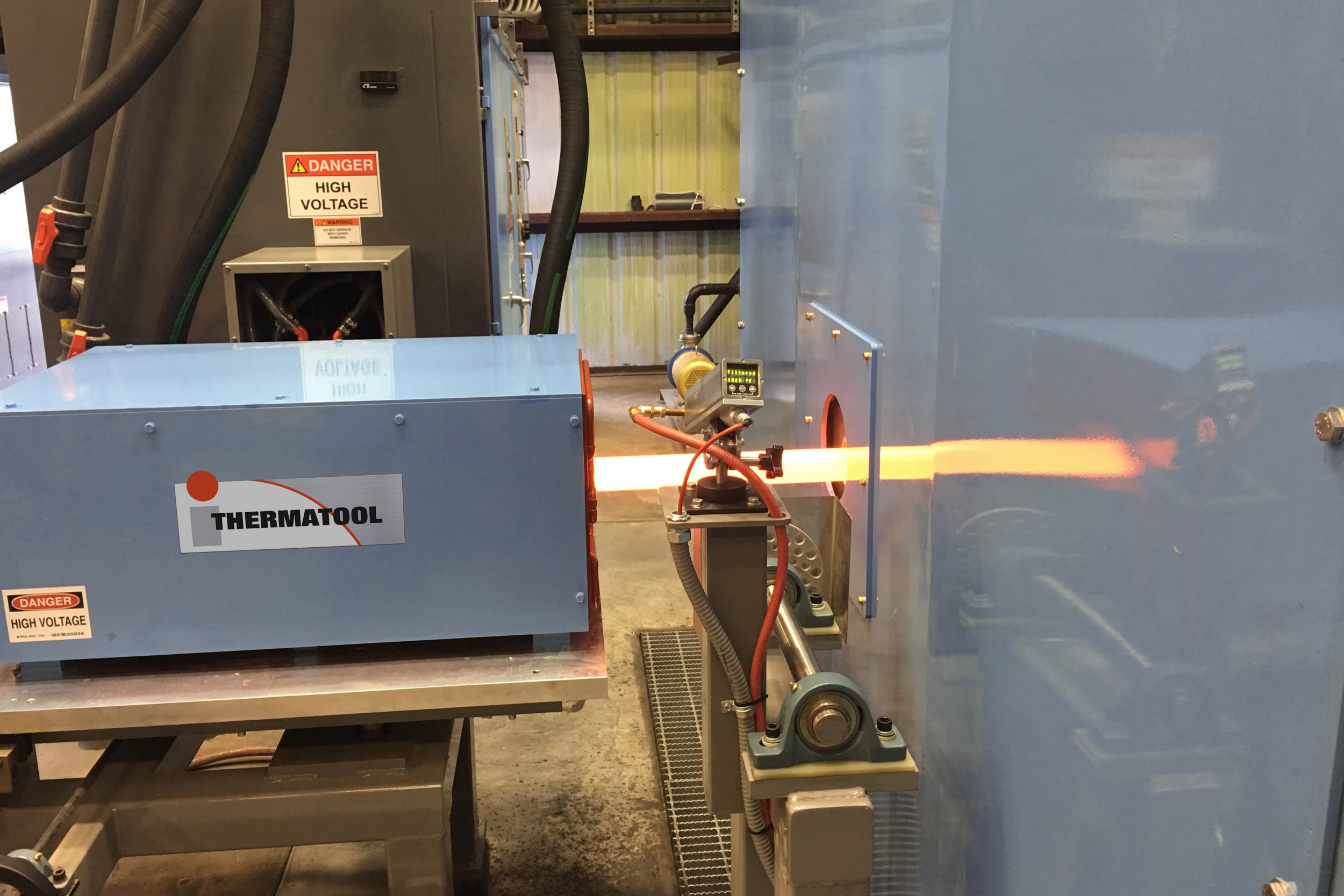

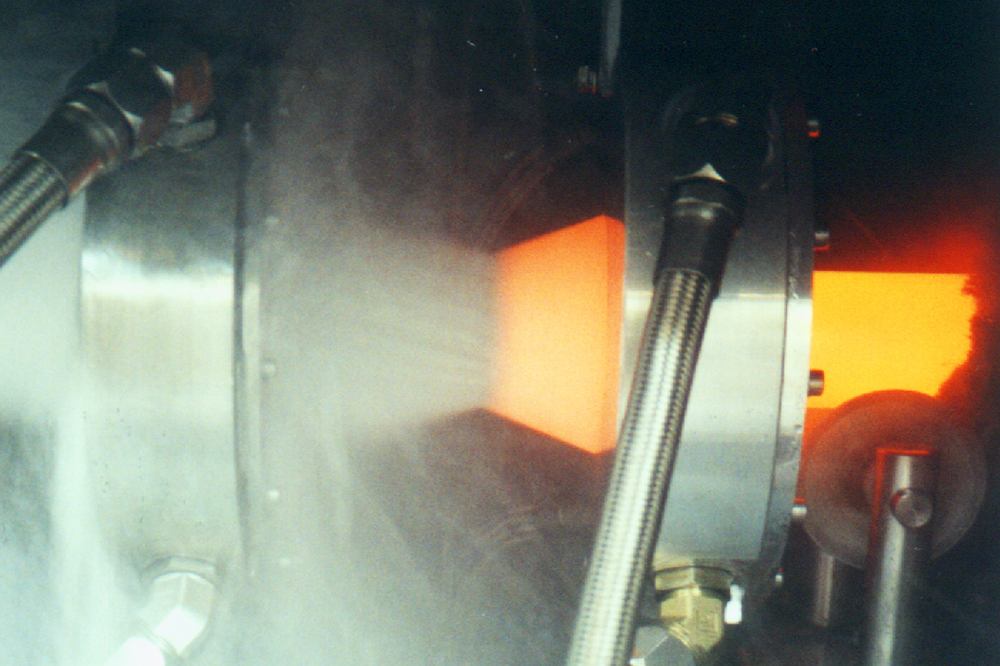

Precision Slot Quench

Thermatool’s unique and patented precision quench delivers unparalleled results in desired mechanical properties. Product straightness is the result of uniform heating followed by precision quenching and can eliminate the need to post heat treat re-straighten. Enhanced metallurgical properties result from programmable control over the quenching process. This is all delivered within a compact equipment footprint. The slot quench rings offer superior control of the hardening process by providing a high velocity and immense symmetrical shaped flow of quenchant. The modular design provides quick change over between product sizes, and precision quenching of large diameter ranges. Variable speed turbine pumps are provided to allow precise control over the quench flow rate, and bounce-back temperatures are programmable for large bar diameters. The quench ring profile prevents scale “clogging” experienced in nozzle type quench barrels. Maintenance is therefore simplified and minimized. A sealed shroud is provided to minimize over spray and water loss.

Features

- High productivity and product yields.

- Equipment setups that are 100% repeatable – better process control.

- Expanded product dimensional range to match upstream production requirements.

- Optimized induction heating efficiency resulting in homogeneous mechanical characteristics.

- Patented precision slot quench technology produces superior strength, increased depth, minimized footprint, and elevated tonage throughput.

Material Handling

Thermatool provides complete material handling solutions that are engineered for specific products and processes. Whether for a Greenfield site or fitting in an existing facility, Thermatool will engineer and build a material handling solution to promote the efficiency of the process. These solutions are designed to be modular and are customized through the specific combination of many standardized components to best serve our customer needs.