Temporary Holding Pots

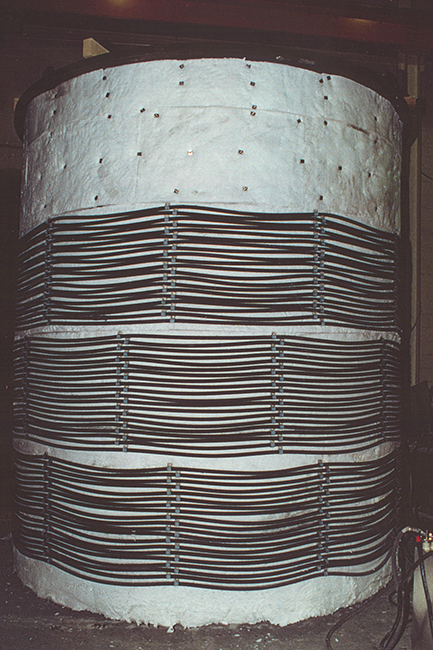

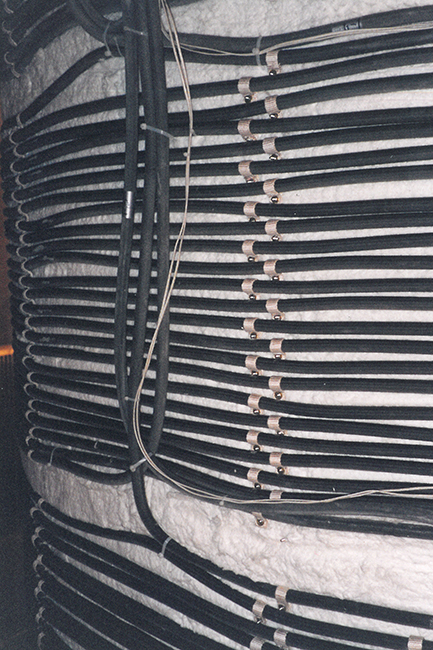

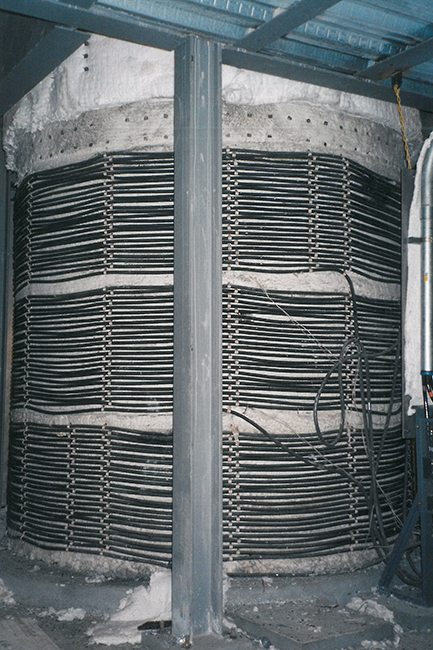

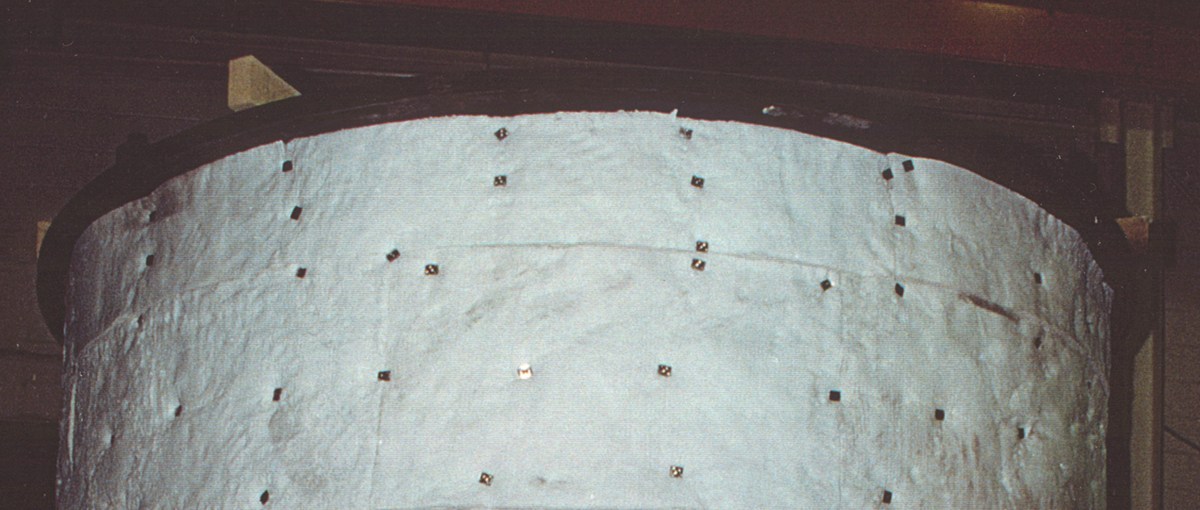

Temporary Holding Pots are designed to quickly and easily facilitate pumping of the molten metal out of the main pot and keep it molten so that it can then be pumped back into the main pot. A small induction power supply unit provides the energy required to maintain the molten metal bath at temperature. These consist of a steel shell wrapped in a thermal blanket and air-cooled cables.

Features

Temporary Holding Pots are designed to quickly and easily facilitate pumping of the molten metal out of the main pot and keep it molten so that it can then be pumped back into the main pot. A small induction power supply unit provides the energy required to maintain the molten metal bath at temperature. They are designed for short-term holding, such as during an inductor change, or other maintenance requirements.

Tech Specs

Contact Inductotherm for Custom Solutions