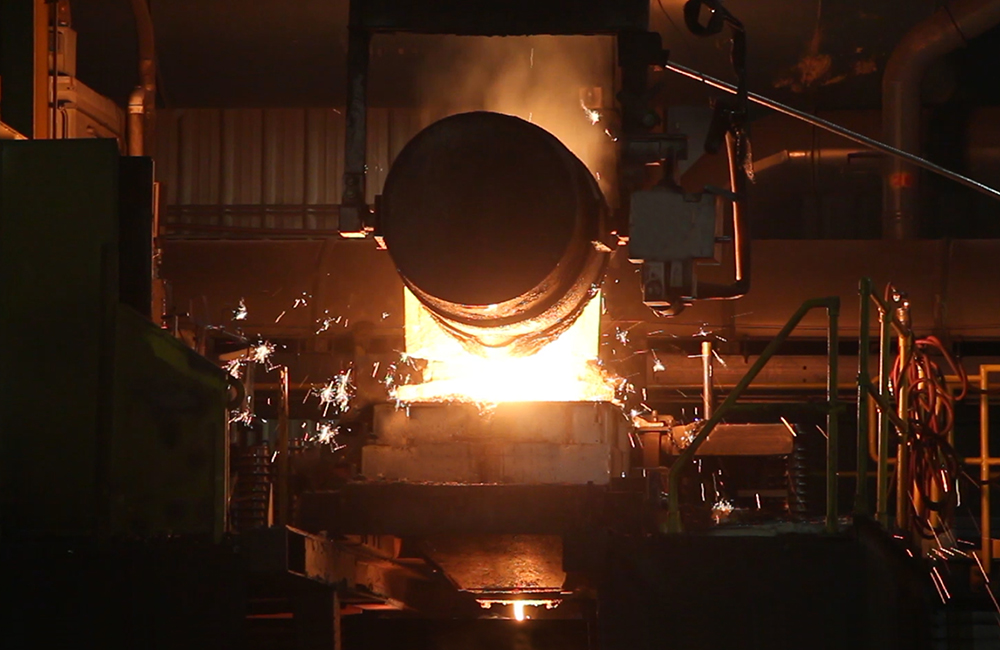

Tundish Furnaces

Unheated Tundish Furnaces are well suited for applications that require multiple alloy flexibility and when hot metal is readily available.

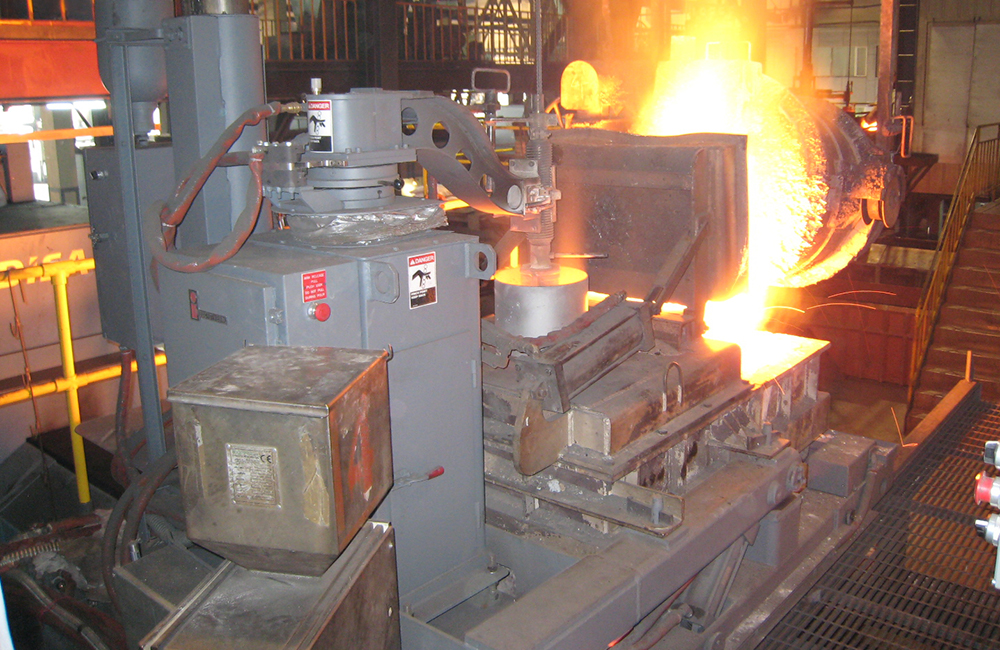

Tundish Automated Pouring Furnaces use a refractory-lined tundish fitted with a stopper rod pouring mechanism that make them ideal for applications needing quick alloy changes of gray, malleable and treated ductile iron. They offer production rates of 3 to 20 metric tons [3.3 to 22 short tons] per hour. The bottom pour design is incorporated within a thermally efficient heavy structural steel vessel. Pouring from the tundish is accomplished through the servo-driven stopper rod mechanism which is accurately controlled with our advanced VISIPOUR® P3® Control Technology. These systems feature VISIPOUR® P3® (Predictive Pour Performance) Technology, the industry’s most reliable and responsive pouring control when coupled to the patented servo-driven stopper rod mechanism, thus making it thermally efficient and easy to maintain.

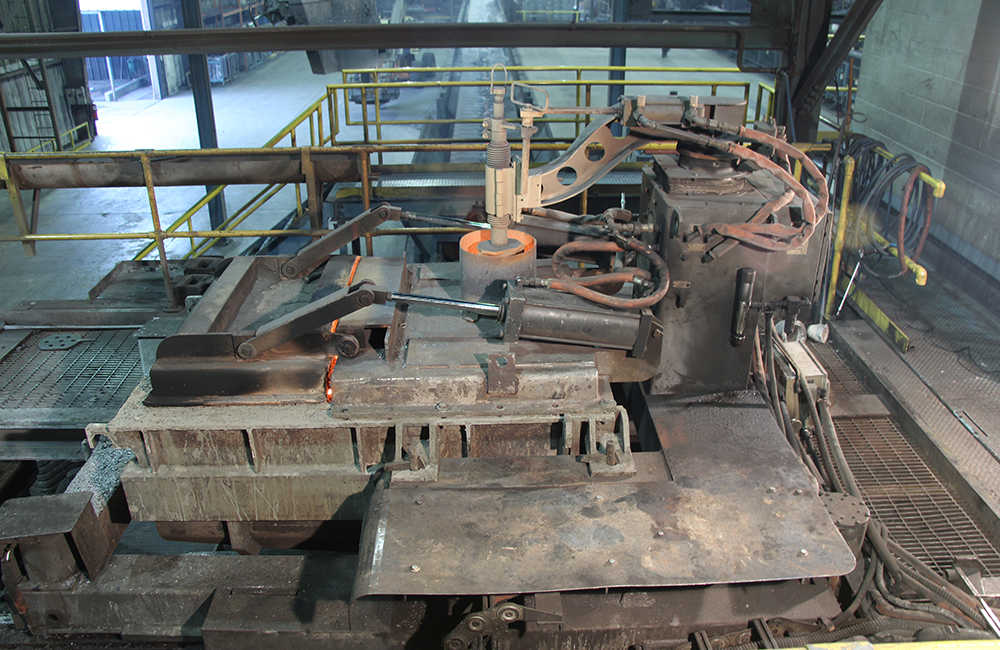

The tundish and the stopper rod mechanism are mounted on a frame which moves on both x and y axes and is able to adjust for varying positioning of the pouring nozzle over the sprue. The frame contains load cells that indicate when metal recharging is required to smooth out the process. Hydraulic tilting eases maintenance and simplifies alloy changes and nozzle replacement. The system is designed for rapid tundish replacement with a spare as it can be quickly removed from its support/tilting cradle. The entire package is fully assembled and tested prior to shipping and is designed for quick assembly to keep installation costs at a minimum.

Control options

VISIPOUR® P³® (Predictive Pour Performance) Control Technology is our breakthrough advancement in Automated Pouring and provides perfect pour precision. This control system is a key component to the most successful Automated Pouring Systems as it suits a wider variety of pouring possibilities.

In addition to VISIPOUR® P³® Control Technology, we offer a variety of automated control platforms to best fit your particular application such as Teach, Teach and Vision, Teach and Weight, Time and Rate, Manual, Direct Pressure Pour, and Positioning Options. Start-up Tundish Systems are also available with an operator-actuated joystick control.

Tech Specs

| Capacities | Standard Features | Optional Features | Factory Tested |

|---|---|---|---|

| 1 to 3 Metric Tons [1.1 to 3.5 Short Tons] | Bottom Pour Stopper Rod Pouring | X-Y Axes Motion | Critical Components |

| Contact Inductotherm for Custom Solutions | Pneumatic Charging Cover | Stopper-Rod Pouring Control Systems | |

| Hydraulic Tilting |